TR34 2003 3rd Edition (Table 4.3) Defined Movement Floor Classifications

In defined movement (DM) areas, Material Handling Equipment (MHE) travel along fixed paths.

Defined movement areas are usually associated with high-level storage racking with very narrow aisles (VNA) in warehouses.

This section of TR34 2003 3rd Edition Table 4.3 provides guidance on controlling surface regularity in defined movement areas which takes into consideration only measurements that are recorded in the front wheel tracks of the Material Handling Equipment (MHE).

It does take into account the relationship between the front axle and read axle of the MHE. To measure this, an alternative method is given in TR34 2003 3rd Edition Appendix C, Table C1.

Features Measured

Property I – the elevational difference in mm between two points 300 mm apart. This feature is measured parallel to the direction of travel of the MHE.

Property II – the change in elevational difference between two consecutive measurements of Property I (points 300mm apart) over 600mm. This feature is measured parallel to the direction of travel of the MHE.

Property III – The elevational difference in mm between the centres of the front load wheels of materials handling equipment.

Properties I, II and III are measured using Dabros Digital Floor Profiler, which can produce produces continuous or semi-continuous readings every 50mm with accuracy of 0.1mm. The interval between the readings can easily be adjusted to client’s requirements (for example, we can take readings every 10mm – 1000mm), however measurements taken every 50mm are sufficient enough to provide true profile of the path of the MHE.

Table 4.3: Permissible limits on Properties I, II and III in defined-movement areas.

Floor classification | MHE lift height | Property I (mm) | Property II (mm) | Property III (mm) | |||||

Wheel track up to 1.5 m | Wheel track over 1.5 m | ||||||||

95% | 100% | 95% | 100% | 95% | 100% | 95% | 100% | ||

Superflat (SF) | Over 13 m | 0.75 | 1.0 | 1.0 | 1.5 | 1.5 | 2.5 | 2.0 | 3.0 |

Category 1 | 8–13 m | 1.5 | 2.5 | 2.5 | 3.5 | 2.5 | 3.5 | 3.0 | 4.5 |

Category 2 | Up to 8 m | 2.5 | 4.0 | 3.25 | 5.0 | 3.5 | 5.0 | 4.0 | 6.0 |

Limits explained

Each of the properties (Property I, Property II and Property III) have 95% and 100% limits.

In order for the floor to comply with any required classification following criteria have to be met:

1. No more than 5% of all measurements for each individual aisle exceeds the 95% limit of the required classification;

Example:

Classification required = Category 1

a) 95% of all Property I measurements recorded must have values of max. 1.5mm or less in order to comply with that classification.

b) 95% of all Property II measurements recorded must have values of max. 2.5mm or less in order to comply with that classification.

c) 95% of all Property III measurements recorded (for wheel track up to 1.5m) must have values of max. 2.5mm or less in order to comply with that classification.

2. None of all measurements for Property 1, Property II and Property IIII in aisle surveyed exceeds the 100% limit of the required classification;

Example:

Classification required = Category 1

a) 100% of all Property I measurements recorded must have values of max. 2.5mm or less in order to comply with that classification.

b) 100% of all Property II measurements recorded must have values of max. 3.5mm or less in order to comply with that classification.

c) 100% of all Property III measurements recorded (for wheel track up to 1.5m) must have values of max. 3.5mm or less in order to comply with that classification.

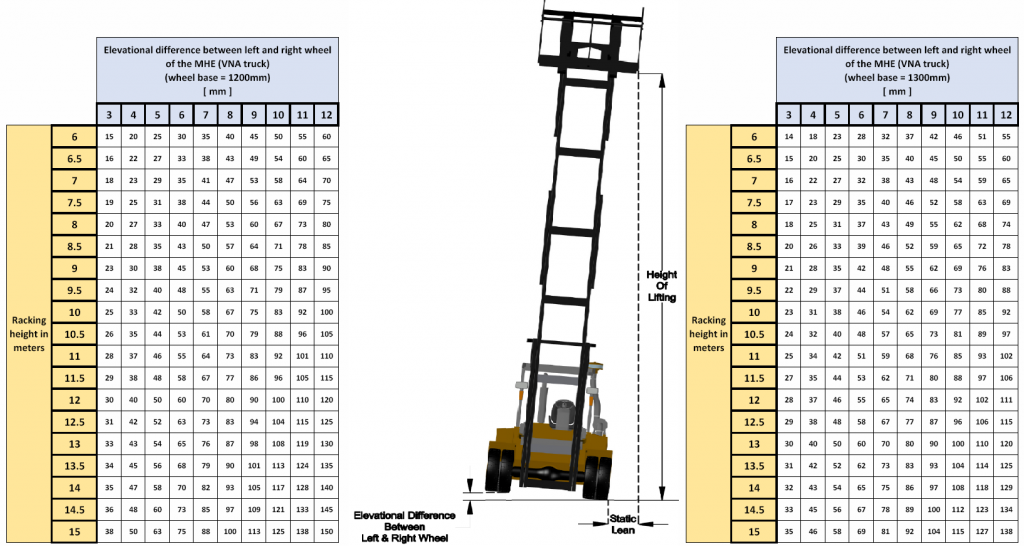

Static Lean

Below is an example of how truck lean increases with lifting height.

This is based on the truck with rigid mast, however due to the engineering tolerances in the mast and the dynamic forces when the VNA truck is in motion, values in the table could increase by up to 3 times.